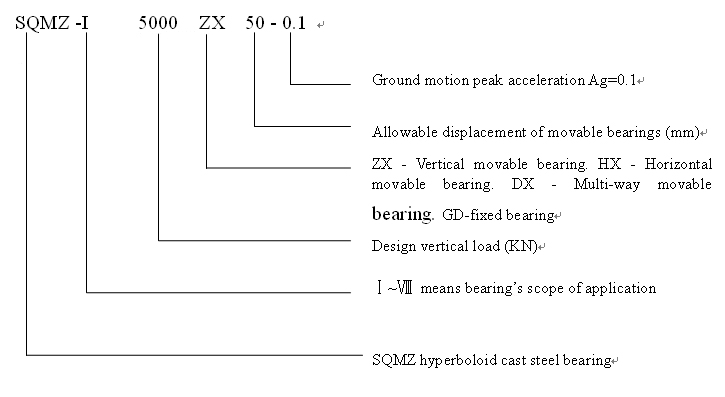

Ⅰ. Code

1. Bearing configuration: In terms of performance, SQMZ bearings are divided into 4 kinds- Vertical movable bearing, horizontal movable bearing, multi-way movable bearing and fixed bearing. It includes upper bearing plate (including plane stainless steel plate), convex hyperboloid liner (including plane PTFE plate), lower bearing plate (including curved surface PTFE plate), bearing anchor bolt, connecting plate and coaming.

2. SQMZ bearings are suitable for passenger r dedicated line (mp h ≤ 350km/h ), mixed passenger and freight line (mp h ≤ 200km/h ), railway concrete beam, steel beam and steel-concrete composite beam.

3. SQMZ bearings are applicable for different kinds of beams with different arrangements.

Ⅱ . SQMZ bearing's performance

1. SQMZ bearings' vertical load, horizontal load, displacement, turning angle and friction coefficient can be designed to suit to bridge and track's actual situation.

2. Design turning angle: in bridge axial direction 0.02rad; in cross- bridge direction 0.02rad.

3. Temperature scope of application : -50 ℃ ~ + 60 ℃

4 bearing can be used in 20 ‰ track gradient , it adopts changing the top surface of top plate or adjusting the concrete of mudsill. After adjusting, the difference between track gradient and top surface's gradient of top plate is less than 4 ‰.

5. Movable bearing's design friction coefficient :

Temperature ≥ -25 ℃ μ≤ 0.03

Temperature < -25 ℃ μ≤ 0.05

Ⅲ . Bearing's specification

1. Bearings' materials

• bearings' steel, PTFE plate, silicone grease and precision rolled stainless steel plate meet the requirement of 《 provisional specification of passenger dedicated bridge pot bearing 》 and attach material specification.

• Slide plates of lateral channel in single-way movable bearings adopt SF-I three-ply cladding sheet . Its structure, chemical properties and appearance quality meet the requirement of TB/T2331.

• Backing plate of adjusting height bearings and bearing linked plate is linked by Q235D. Its chemical and mechanical properties meet the requirement of GB700-1988.

• Hard chromium : surface coating's thickness of SQMZ bearings convex hyperboloid liner is more than 100μm of Hard chromium , steel plate plated chromium is no surface pore, no contraction crack and scar, which meet the the requirement of GB/T11379.

2. Bearing making

• The dimension error of bearings' parts and gap erro is accordant with the design drawing. Dimension error of no-described parts is accordant with the grade M of GB/T1804-2000.

• Clearance value △ of profile tolerance between convex hyperboloid liner and fovea hyperboloid on lower bearing plate in bridge axial direction or cross-bridge direction :

L > 600mm , △≤ 0.003L ;

L ≤ 600mm , △≤ 0.2mm ;

L is length of horizontal projection of hyperboloid PTFE plate in in bridge axial direction or cross-bridge direction .

3. Anticorrosion and dustproof of bearings

• Bearings, bolts of beam base, anchor bolts and standard of bolts meet the requirement of 《 Steel Bearing of Railway Bridge 》 .

• During bearings installation, dustproof devices installed must be to accordance with design drawing.

4. Assembly of bridge bearing

• Each part of bearing has kite mark from department of quality determination, purchased parts attach related project inspection report or certificate of soundness.

• SQMZ bearings are set up on the appropriative platform. After assembly, non-parallelism between upper and lower surfaces is less than 2‰ of long edge. Vertical projection misalignment deviation of upper and lower bearing plate's symmetrical line is ± 0.5mm .

• When sticking SQMZ bearings' fovea hyperboloid plate and lower bearing plate, matching convex hyperboloid liners as molding formwork are adopted to press.

• After bearings' assembly, the total height deviation:

Vertical load < 20000kN, deviation ≤ ± 2mm

Vertical load ≥ 20000kN, deviation ≤ ± 3mm

• Exposed height deviation of PTFE plate's 4 points:

0 ~ + 0.2 mm

• After bearings' assembly, the sliding clearance deviation of non active direction is ± 0.2mm .

Ⅳ . Inspection rules

SQMZ bearings' inspection is divided into material inspection, factory inspection and model inspection.

4.1 SQMZ bearings' material and parts' inspection item and inspection period should meet the requirement of table 1. Materials and purchased parts not only have certificate of soundness, but attach rechecked report.

Table1. SQMZ bearing's material and parts' inspection (Enter Factory)

|

Testing item |

Testing content |

Detection criterion |

Testing frequency |

|

PTFE |

Mechanical property |

No. 1.1 |

Once of every batch material ( ≤ 200Kg ) |

|

Geometry size |

Design drawing |

Each package |

|

Steel casting |

Crack & defect |

TB/T2331 |

Each package |

|

Mechanical property |

No. 1.1 |

Per heat |

|

Stainless steel plate |

Material |

GB3280 |

Every batch ( ≤ 1000Kg ) |

|

Roughness |

Ra1.6~Ra0.8 |

|

Anchor bolt |

Mechanical property |

GB/T 3077 |

Every batch |

|

Steel plate |

Mechanical property |

GB/T1591 |

Every batch |

|

Silicone grease |

Mechanical property |

HG/T2502-1993 |

Every batch ( ≤ 50Kg ) |

|

Hard chromium |

Thickness |

GB/T4956 |

Every batch plating articles |

|

Roughness |

Ra1.6~Ra0.8 |

4.2 SQMZ bearings' material and parts' inspection item and inspection period should meet the requirement of table 2. Materials and purchased parts not only have certificate of soundness, but attach rechecked report

.

Table2. SQMZ bearing's factory inspection

|

Testing item |

Detection criterion |

Allowable deviation (mm) |

Testing frequency |

|

Bolt-hole center distance on upper bearing plate |

Design drawing |

± 0.5 |

|

|

Bolt-hole center distance on lower bearing plate |

Design drawing |

± 1 |

|

|

P rofile tolerance between convex hyperboloid liner and fovea hyperboloid on lower bearing plate |

Design drawing |

No. 2.2 |

|

|

Exposed height of PTFE plate |

Design drawing |

+0.2 |

|

|

The plane dimension and arrangement of lipid groove |

TB/T2331

-2004 |

Storage groove space: ± 0.5 |

|

|

Storage groove depth: ± 0.5 |

|

|

Storage groove diameter: ± 1 |

|

|

Height of bearings' installation |

Design drawing |

No. 4.4 |

Each bearing |

|

Non-active direction sliding space of vertical movable and fixed bearings |

Design drawing |

No. 4.6 |

|

|

surface anti-corrosion of bearings |

Design drawing |

No. 3.1 |

|

4.3 SQMZ bearings' material and parts' inspection item and inspection period should meet the requirement of table 3.

Table3. SQMZ bearing's model inspection

|

Testing item |

Testing content |

Detection criterion |

Testing frequency |

|

Performance of materials and parts |

No. 4.1 |

Same as Table 1 |

1% of the total bearings |

|

bearing factory inspection |

No. 4.2 |

Same as Table 2 |

1% of the total bearings |

|

PTFE plate |

Density |

No. 1.1 |

2.14~ 2.20 g /cm3 |

1% of the total bearings |

|

Tensile strength |

≥ 30MPa |

|

Elongation at break |

≥300% |

|

Ball indentation hardness |

23~33Mpa |

|

friction coefficient |

≤ 0.02 |

|

Line attrition loss of PTFE plate |

No. 1.1 |

≤ 30μm/km |

Random (choose two) |

4.4 Judgment of inspection result meets the requirement of No 7.3 in 《 provisional specification of SQMZ bridge bearings 》

4.5 In order to insure the quality of SQMZ bearings, it is necessary to implement supervision system to monitor the making process and quality inspection of bearings.

Ⅴ . Label, package, storage and transportation

Every single bearing should have permanent label which includes product name, specification, main technical figures (vertical load, displacement, temperature scope of application, ground motion peak acceleration etc.), complete name of manufactory, factory number and date of manufacture.

After bearing assembly, it is linked and fixed temporally, inner layer adopts plastic waterproof package, and outer layer adopts crashworthy wood box or iron box to pack. Enlacing bearings firmly is convenient for loading and unloading. Outer surface of packing box marks product name, specification, date of manufacture, volume and quality. Inside of packing box attaches product qualification certificate, quality inspection sheet, operating instruction and packing list. All above documents are enclosed into a plastic bag. Dustproof hoods, bolts and so on can not be packed with bearings, can be packed in other wood box.

Operation instruction of bearings including bearings' structure, shape, dimension, diagram, notice of installation, requirement of concrete grade in connecting parts of bearings, maintenance regulation of bearings and so on.

During the storage and transportation of bearing, some reliable protection measures are necessary, for example, avoiding sunshine and, rain and snow trickle leaching, keeping clean, prohibiting contacting with acid, alkali, oil, organic solvent which may affect the quality of bearings, and keeping distance over 1 m with heat source.

After arrival and installation of bearings, cooperate construction unit and related unit to deal with transfer procedure.

The bearing is packed completely and the appearance is no damage.