Home >> Machinery >> Light Industy Machinery >> Woodworking Machinery >> Details

Drum Debarker

Log Debarker, Drum Debarker[09-05-19 10:20:43]

Introduction of Log Debarker

CLIMA is the leading Log Debarker manufacturer and exporter from China. We develop and manufacture series of Ring Debarker and Drum Debarker with great performance & reliability.

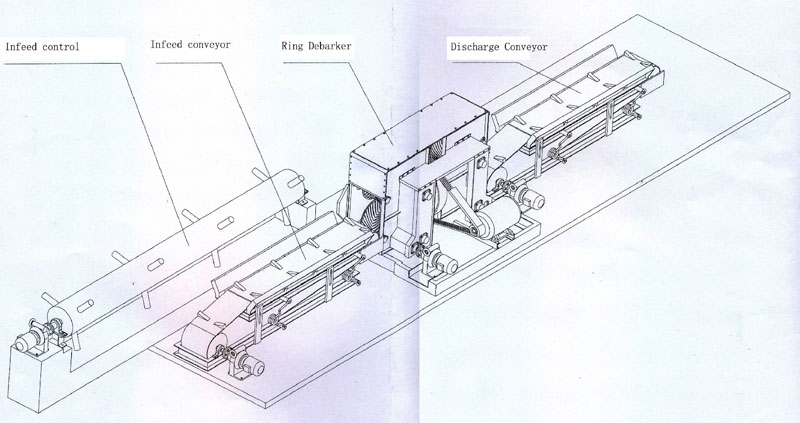

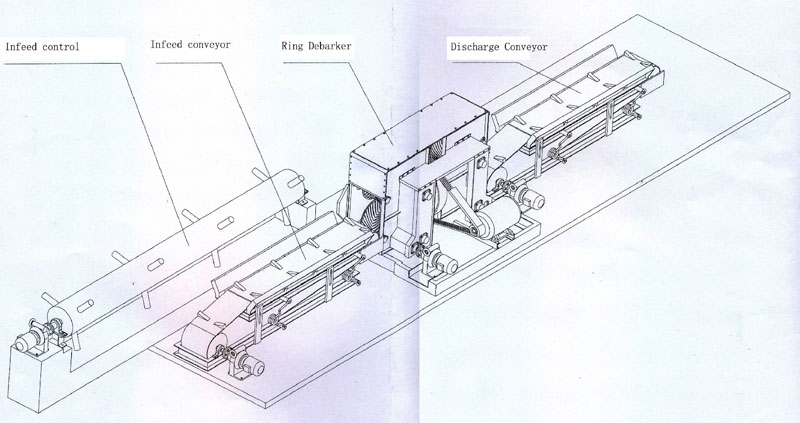

Ring Debarker

Low initial investment. & High production capacity—Best choice for small and medium scale factory. We have the most advanced technology in debarking the small size logs. The minimum diameter of log could even up to 1.8 cm. We have 6 models of ring debarker, TPHBD 130, TPHBD 160, TPHBD 200, TPHBD 220, TPHBY 320 and TPHBY500, which can satisfy our clients different need, especially the small-scale factory.

Low initial investment. & High production capacity—Best choice for small and medium scale factory. We have the most advanced technology in debarking the small size logs. The minimum diameter of log could even up to 1.8 cm. We have 6 models of ring debarker, TPHBD 130, TPHBD 160, TPHBD 200, TPHBD 220, TPHBY 320 and TPHBY500, which can satisfy our clients different need, especially the small-scale factory.Drum Debarker

we also could provide 5 models of drum debarker, TPZBG 2400, TPZBG 9000, TPZBG 13500, TPZBG 18000 and TPZBG 27000, which can fulfill the medium-size and large-scale factory need. We own all the patents of these products.

Our products have been exported to more than 11 countries all around world including Africa countries and India. All our Parts & Service representatives are experienced professionals who take pride in providing our customers with the best service possible.

Our products have been exported to more than 11 countries all around world including Africa countries and India. All our Parts & Service representatives are experienced professionals who take pride in providing our customers with the best service possible.

General Process of Log Debarker

Debarkers are utilized to remove the bark from logs or stems (trees) prior to sawing or chipping. There are basically four types of log debarkers: ring debarker, drum debarker, Rosser head debarker and flail debarker.

Ring Debarkers:

Ring Debarkers:

Logs or stems are selected and fed linearly into the debarking system. There usually is a centering infeed in front of the debarkers. This infeed centers the log to the center of the ring.

The debarker has infeed rolls to guide and feed the log or stem into the rotor. These rolls can be spike rolls or herringbone rolls. Typically there will be one or two sets of these rolls. The ring, or rotor, rotates around the log as it is fed through the debarker. There are tool arms on the ring that are pressurized, typically with air bags. This pressure squeezes the tool tips against the bark and pulls the bark away at the cambium layer. Debarkers can have a single ring or dual rings. There are outfeed rolls, the same as the infeed rolls, to pull the log or stem out of the debarker. Ring debarkers are primarily used in high speed softwood sawmill applications.

Ring Debarkers:

Ring Debarkers:Logs or stems are selected and fed linearly into the debarking system. There usually is a centering infeed in front of the debarkers. This infeed centers the log to the center of the ring.

The debarker has infeed rolls to guide and feed the log or stem into the rotor. These rolls can be spike rolls or herringbone rolls. Typically there will be one or two sets of these rolls. The ring, or rotor, rotates around the log as it is fed through the debarker. There are tool arms on the ring that are pressurized, typically with air bags. This pressure squeezes the tool tips against the bark and pulls the bark away at the cambium layer. Debarkers can have a single ring or dual rings. There are outfeed rolls, the same as the infeed rolls, to pull the log or stem out of the debarker. Ring debarkers are primarily used in high speed softwood sawmill applications.

Drum Debarker

Logs or stems are batch fed linearly into the drum debarker. The drum rotates and tumbles the logs and the bark is removed by rubbing against the drum walls and other fibre in the drum. A variation to the drum debarker is the Fuji King and Brunette Industries reclaimer debarkers. These are bin type debarkers utilizing longitudinal rolls, or rotors, with attachments using a combination of mechanical and log-to-log contact to remove the bark. Drum debarkers are primarily used in larger whole log chipping applications.

Logs or stems are batch fed linearly into the drum debarker. The drum rotates and tumbles the logs and the bark is removed by rubbing against the drum walls and other fibre in the drum. A variation to the drum debarker is the Fuji King and Brunette Industries reclaimer debarkers. These are bin type debarkers utilizing longitudinal rolls, or rotors, with attachments using a combination of mechanical and log-to-log contact to remove the bark. Drum debarkers are primarily used in larger whole log chipping applications.

Equipment information of Log Debarker

All the data are base on our 30 debarkers plant and are only for customers' reference, we can adjust the specification according to your requirements.

Just a few of them have been listed , please contact us if you want any other kinds of machines.

|

||||||||||||||||||||||||

|

||||||||||||||||||||||||

|

||||||||||||||||||||||||

|

||||||||||||||||||||||||

|

||||||||||||||||||||||||

|

||||||||||||||||||||||||

After the shipment of ring debarker and log debarker, we can sent engineers to customers' workshop for installation. Local staffs who will operate ring debarker will also be trained during the assembly.

Chinese

Chinese English

English German

German Spanish

Spanish French

French Italian

Italian Portuguese

Portuguese Japanese

Japanese Korean

Korean Arabic

Arabic Russian

Russian