Home >> Machinery >> Food Processing Machinery >> Confectionery Machinery >> Details

Biscuit Production Line

Our automatic biscuit processing line, with original design and compact structure, is developed on the base of European technology. All working procedures from feeding, calendering, shaping, wastage recovering, drying to cooling can be accomplished at the same time. Hundreds of moulds and dozens of technology formulas make it possible to produce all kinds of popular biscuits, such as cream biscuit,layer biscuit calcium biscuit, multi-vitamin biscuit, vegetable bisuit, etc.

Our automatic biscuit processing line, with original design and compact structure, is developed on the base of European technology. All working procedures from feeding, calendering, shaping, wastage recovering, drying to cooling can be accomplished at the same time. Hundreds of moulds and dozens of technology formulas make it possible to produce all kinds of popular biscuits, such as cream biscuit,layer biscuit calcium biscuit, multi-vitamin biscuit, vegetable bisuit, etc.

Complete biscuit producing line may be combined freely according to the condition of customers workshop and requirement of biscuit technology. These all can reach the ideal purpose. The line use imported electric components and its speeds are changed by frequency conversion with high accuracy.

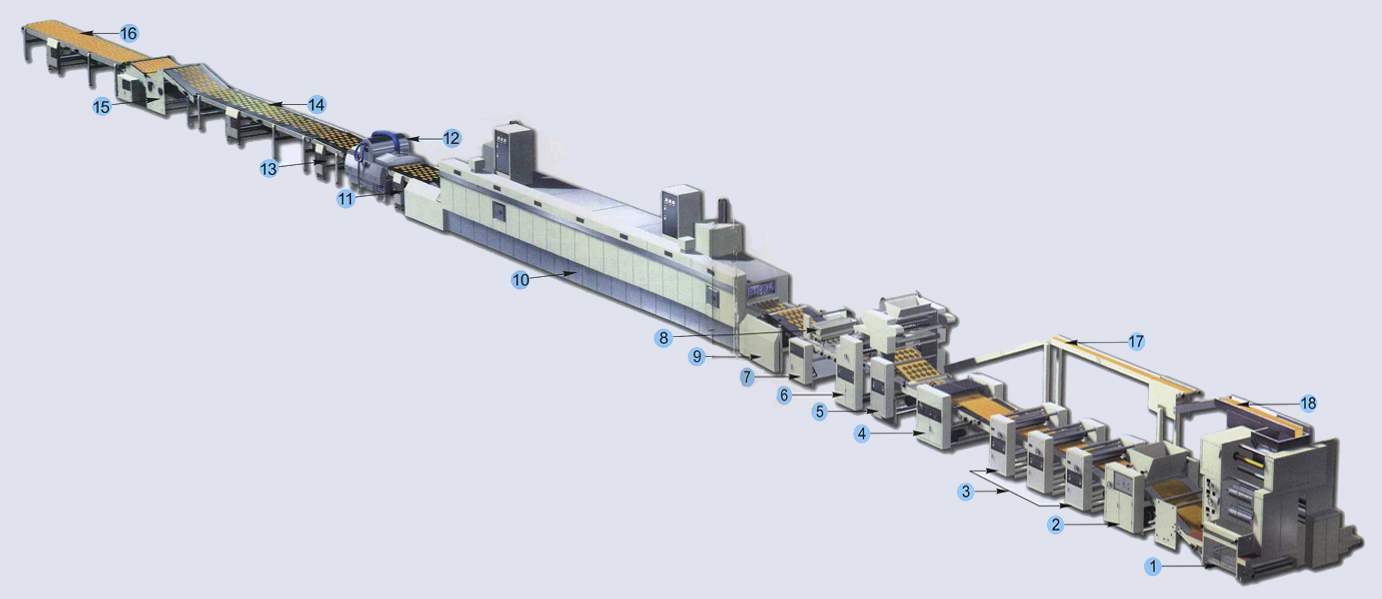

Biscuit production line

| 1.Vetical laminator or horizontal laminator | 2. Combine sheeter |

| 3. Gauge roll | 4. Rotary cutter or reciprocating cutter |

| 5. Rest conveyor | 6. Vertical or horizontal rotary moulder |

| 7. Drive and panner | 8. Salt/sugar sprinkler |

| 9. Over drive and over tension | 10. Hot wind circulation baking oven |

| 11. Peeling machine | 12. Oil spray machine |

| 13. Oil filter | 14. Cooling conveyor |

| 15. Biscuit stacking machine | 16. Packing conveyor |

| 17. Side scrap return system | 18. Reciprocating distriluor |

Processing flowchart:

Dough making → Biscuit forming → Baking → Oil sprayer → Cooling → Stacking

|

|

|

|

|

|

Round shaped |

Cookie |

Central fiiled |

Square shaped |

Several layers |

Note:

1. Diversified biscuit . The capacity is 100-1000kg/H

2. Main electronic equipments are adopted from Siemens。

3. All machines are made by our Company ,vendee can check it at any moment during the making period.

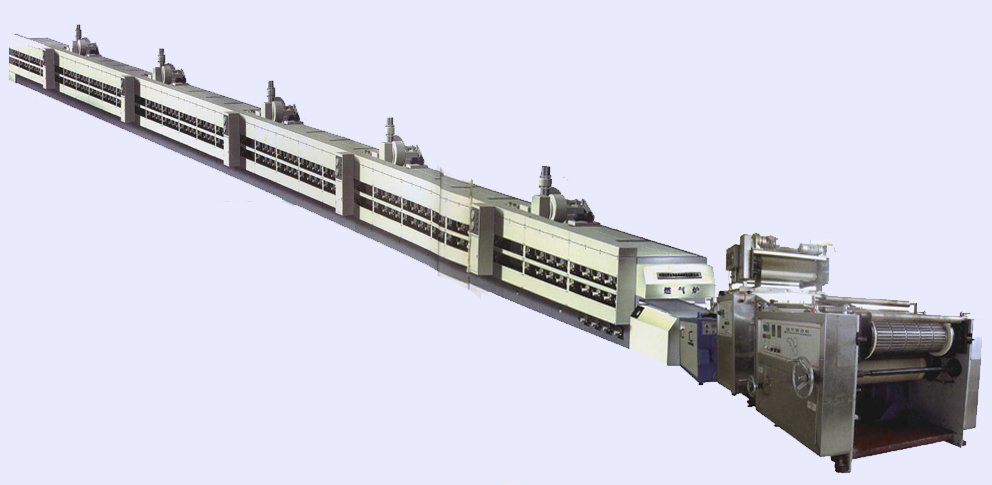

Direct gas oven for biscuit drying

1. The machine is heated with gas. Rapid heating up and energy saving.

2. The oven is grouped into heat control zones. The top and buttom heat are independently adjustable and preset. The measured temperature will be displayed in digital form.

3. To allow independent movement of the chamber to relieve stresses when expanding or contracting.

4. High-quality thermal insulating material is used to get good insulation and efficient fuel usage.

5. Steelwork, ducts and chambers paint with high temperature (400 degree) silvery paint. Outer covers paint.

6. Oven band level: 1100mm

7. Fully automatic PID temperature control and automatic constant temperature.

8. Highest temperature: 360 degree.

9. Great control flexibility and perfect safety precautions.

10. PLC control, touch screen control.

11. It can meet the technological requirement for production of different biscuits.

After the shipping of biscuit production line, we will sent engineers to local workshop, for the assembly of the biscuit production line. Our engineers will stay there until the machine runs in normal state. During the commission, local workers will also be trained.

Chinese

Chinese English

English German

German Spanish

Spanish French

French Italian

Italian Portuguese

Portuguese Japanese

Japanese Korean

Korean Arabic

Arabic Russian

Russian